What is Electrosurgical Unit?

Electrosurgical unit refers to various techniques utilizing electricity to induce thermal damage to tissues via dehydration, coagulation, or vaporization. An Electrosurgical Unit (ESU) comprises a generator and a handpiece equipped with one or more electrodes. Control of the device is facilitated through a switch on the handpiece or via a foot switch. Electrical surgical cables are crucial for electrical surgical systems.Electrosurgical generators can generate diverse electrical waveforms, with alterations in these waveforms leading to corresponding changes in tissue effects.

What are the types of electrosurgery?

The two primary types of electrosurgical unit commonly employed are high-frequency electrosurgery and electrocautery.

High-frequency electrosurgery encompasses four distinct techniques: electrocoagulation, electrodesiccation, electrofulguration, and electrosection. These methods utilize high-frequency alternating current, which generates heat via resistance as it traverses through tissues.

Electrocautery involves the direct application of heat to tissues. Unlike high-frequency electrosurgery, the current is not passed through tissues but is instead used to heat handheld components that are subsequently applied to tissues.

What are the accessories for electrosurgical units?

To ensure the functionality of an electrosurgical device, various components are required. Typically, an electrosurgical system consists of six main components: the generator, handpiece, cables, electrodes, dispersive pad/return electrode, and foot pedal/controller. Among these, one crucial component is the ESU cable.

How does an electrosurgical unit work?

To begin, it’s essential to clarify the term “electrosurgical unit,” which can refer to either the generator alone or the entire electrosurgical system encompassing the generator, handpiece, foot pedal, etc.

At the heart of an electrosurgical unit lies the generator, serving as the control center for many functions within the system.

Here’s how an electrosurgical unit operates:

- The generator supplies power to the electrode located at the handpiece’s end.

- For cutting operations, a continuous radio frequency (RF) wave is utilized, inducing friction within cells until they rupture.

- For coagulation, an intermittent RF wave with a high peak is employed.

- In monopolar instruments, current flows from the electrode to the dispersive pad/return electrode upon contact with the body, completing the circuit back to the generator.

- In bipolar instruments, the electrode itself closes the circuit, eliminating the need for a dispersive pad/return electrode.

- Throughout the procedure, the physician regulates current flow by manipulating the foot pedal/control, akin to operating an accelerator in a vehicle.

Why are electrosurgical cables important to the electrosurgical system?

Electrosurgical cables play a vital role in connecting the handpiece, electrode, return electrode, and foot pedal to the generator within an electrosurgical system. Often overlooked, these cables serve as the backbone of the system, facilitating seamless communication and operation during crucial procedures.

When discussing electrosurgery, the handpiece (also known as the “pen” or “pencil”) is frequently the primary focus. However, while essential, the handpiece alone does not guarantee a successful electrosurgical procedure.

The cables facilitating power and information exchange between the generator and other peripheral components are a crucial yet often underestimated aspect of the electrosurgical system. They play a significant role in reducing the likelihood of surgical errors and ensuring the completion of the electrosurgical circuit.

- Mitigating the Risk of Surgical Errors

The cable connecting the generator to the handpiece plays a crucial role in mitigating potential surgical errors, although this may not be immediately apparent.

This is achieved through the design of the connector, which is keyed to ensure it can only be plugged into a specific receptacle on the generator.

For instance…the connector for a bipolar electrode is keyed differently from that of a monopolar electrode.

If a physician were to mistakenly plug a monopolar device into a bipolar receptacle, or vice versa, it could result in various complications for the patient, including severe electrical burns.

By keying the connectors differently, the risk of such errors is reduced, preventing the wrong device(s) from being connected during surgery.

- Completing the Electrosurgical Circuit

Electrosurgical cables are essential for completing the electrical “circuit” within an electrosurgical system. Electrosurgery employs alternating current, which necessitates a complete electrical circuit for proper function.

In monopolar surgery, the current travels from the generator to the handpiece via a cable. Subsequently, it flows through the body to the return electrode, where it is then routed back to the generator via another cable. Without these essential cables, the electrosurgical circuit cannot be closed, rendering the system inoperable.

Design method of electrosurgical unit cable

Designing surgical blade cables involves considering various aspects, including functional requirements, safety, reliability, and ease of use. Here are some key factors and methods to consider when designing surgical blade cables:

Functional Requirements Analysis: Firstly, it’s essential to clarify the functional requirements of the surgical blade cables, including power delivery, signal transmission, data acquisition, etc. Different types of surgical blade cables may have different functional requirements. For example, some may need to provide high-frequency electrical currents, while others may need to transmit image signals or physiological monitoring data.

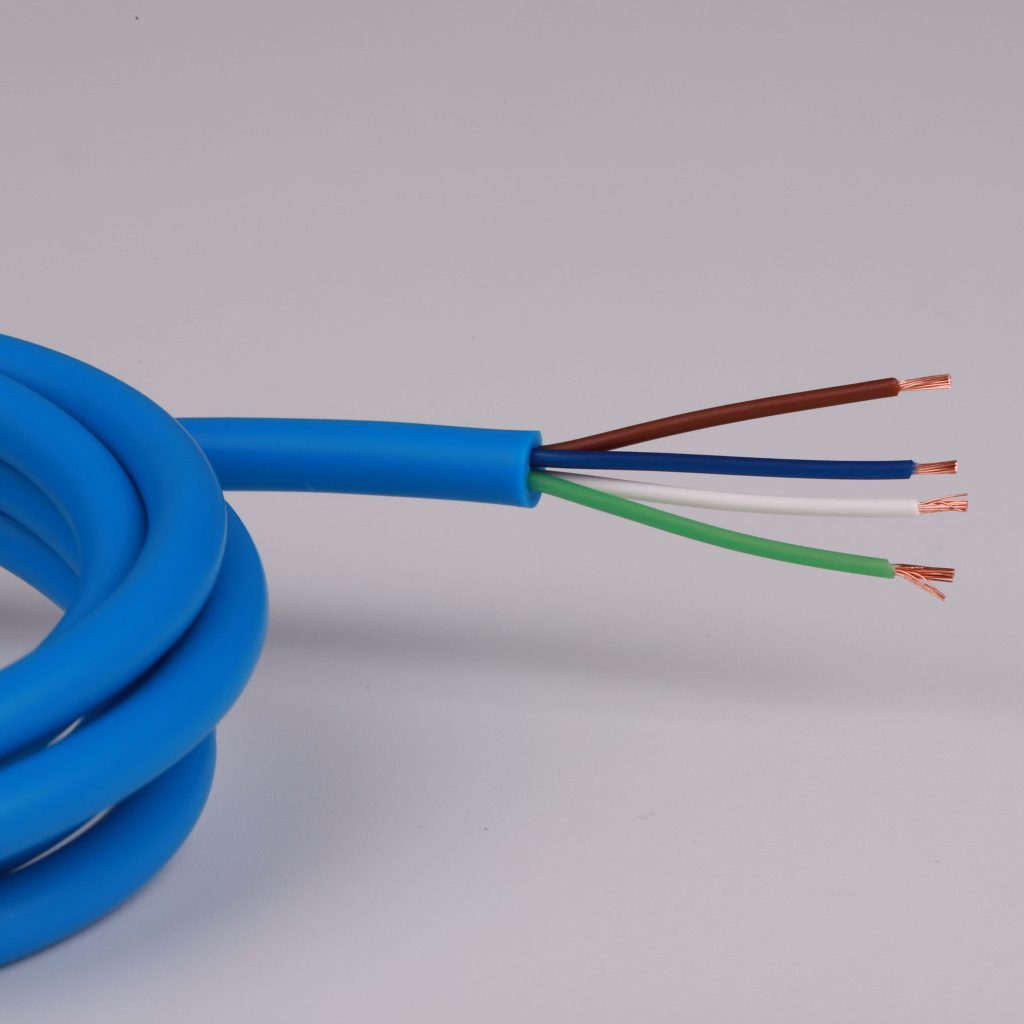

Material Selection: Select appropriate materials based on functional requirements and usage environments. Consider properties such as conductivity, insulation, high-temperature resistance, flexibility, etc. Common materials include silicone, polyurethane, PVC, etc. Surgical blade cables typically use conductive materials with high conductivity and good corrosion resistance. Common conductor materials include copper, copper alloys, silver, tin-plated copper.

Electrical Design: For surgical blade cables requiring power delivery or signal transmission, electrical design is necessary. This involves determining the size, materials, and wiring configuration of the conductors to ensure sufficient current carrying capacity and signal transmission quality.

Safety Considerations: During the design process, safety risks that surgical blade cables may encounter during use, such as electric shock or infection, need to be considered. Therefore, measures should be taken to ensure that the cables have good insulation, wear resistance, and antimicrobial properties, and comply with relevant medical device standards and regulations.

Mechanical Design: For surgical blade cables requiring durability and flexibility, mechanical design is essential. This includes determining parameters such as outer diameter, internal structure, bending radius, etc., to ensure that the cables are less prone to breakage or damage during use.

We offer both reusable and disposable Monopolar & Bipolar cables. Monopolar & Bipolar cables consist of connectors and cable.

Disposable Monopolar & Bipolar cable:

1.Made of high-quality PVC material.

2.Able to withstand high voltages up to 5000V.

Reusable Monopolar & Bipolar cable:

1.Constructed from high-quality medical-grade soft silicone cable.

2.Suitable for high-temperature and high-pressure disinfection.

3.Capable of withstanding temperatures up to 135 degrees Celsius and high voltages up to 5000V.

4.Utilizing silver-plated copper conductors to further enhance the conductivity of the wires, ensuring efficient and stable current transmission for the electrosurgical cable. Additionally, the cables exhibit excellent corrosion resistance and oxidation resistance. They also enhance the mechanical strength of the conductors, improving their tensile and bending resistance, thereby reducing the risk of breakage and damage.